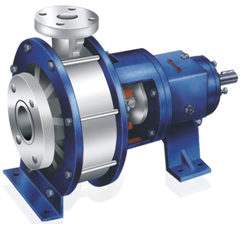

Polypropropylene(PP) Pump - CWPPC

------------------------------------CARE-WELL Polypropylene Pumps are well designed for Handling of Corrosive Chemicals like Acids, Alkalis Solvents etc., Polypropylene Pumps are widely used in all Chemical Industries. Polypropylene Pumps are used in Chemical Processing, Transferring of Corrosive Chemicals, Loading and Unloading of road tankers, Effluent Treatment Plants, Re-circulation of Chemicals, Filter press in Dyes Industries, Electro Plating, De-scaling, Water Treatment, Scrubbing of Corrosive Gases. Our Wide range of Pumps & Quality of Pumps are reflected by customer appreciation and repeat orders. Polypropylene Pumps have the capacity and capability to accept and execute customer requirements.

These pump can operate at 1440 rpm & 2800 rpm. Availabe in Horizontal As well as in Vertical series.

CWPPC Material of Construction

|

Part |

Material for Standard |

|

Impeller |

Polypropylene |

|

Shaft |

EN—8/ SS-316 |

|

Shaft sleeve |

CERAMIC / SS-316 |

|

Sealing |

Gland Packing/

Mechanical Seal |

|

Casing |

Polypropylene |

CWPPC Pump Technical Specification

|

PERFORMANCE

TABLE AT 1440 RPM |

||||||||||||||

|

PUMP

MODEL |

SUCTION(MM) × DELIVERY(MM) |

IMPELLER (MM) |

HP/RPM |

TOTAL

HEAD IN METERS/ CAPACITY

IN M3/HR |

||||||||||

|

|

|

|

|

5 |

6 |

8 |

10 |

11 |

12 |

13 |

14 |

15 |

17 |

|

|

CWPPC-2S |

40 × 40 |

195 |

2 /1400 |

25 |

20 |

12 |

6 |

2 |

|

|

|

|

|

|

|

CWPPC-3S |

75 × 40 |

205 |

3/1400 |

|

40 |

30 |

23 |

19 |

15 |

10 |

|

|

|

|

|

CWPPC-5S |

75 × 50 |

205 |

5/1400 |

|

|

|

37 |

33 |

28 |

24 |

20 |

10 |

6 |

|

|

PERFORMANCE

TABLE AT 2800 RPM |

|||||||||||||||

|

PUMP

MODEL |

SUCTION(MM) × DELIVERY(MM) |

IMPELLER (MM) |

HP/RPM |

TOTAL

HEAD IN METERS/ CAPACITY

IN M3/HR |

|||||||||||

|

|

|

|

|

5 |

8 |

10 |

12 |

15 |

18 |

20 |

25 |

30 |

35 |

40 |

45 |

|

CWPPC-1 |

25 × 25 |

100 |

1/2800 |

10 |

8 |

6 |

3 |

|

|

|

|

|

|

|

|

|

CWPPC-2 |

40 × 40 |

140 |

2/2800 |

|

11 |

9 |

7 |

3 |

|

|

|

|

|

|

|

|

CWPPC-3 |

40 × 40 |

150 |

3/2800 |

|

|

26 |

23 |

20 |

10 |

5 |

|

|

|

|

|

|

CWPPC-5 |

75 × 40 |

160 |

5/2800 |

|

|

35 |

32 |

30 |

27 |

25 |

15 |

|

|

|

|

|

CWPPC-7 |

75 × 50 |

160 |

7.5/2800 |

|

|

|

50 |

46 |

42 |

38 |

32 |

25 |

15 |

|

|

|

CWPPC-10 |

75 × 40 |

190 |

10/2800 |

|

|

|

|

|

|

|

45 |

42 |

25 |

15 |

4 |

“CWPPC VERTICAL SERIES”

|

PERFORMANCE

TABLE AT 2800 RPM |

||||||||||||||||

|

PUMP

MODEL |

SUCTION(MM) × DELIVERY(MM) |

IMPELLER (MM) |

HP/RPM |

TOTAL

HEAD IN METERS/ CAPACITY

IN M3/HR |

||||||||||||

|

|

|

|

|

7 |

8 |

10 |

11 |

12 |

15 |

16 |

20 |

25 |

30 |

32 |

35 |

40 |

|

CWPPC-1 VG |

25 × 25 |

100 |

1/2800 |

11 |

9 |

6 |

5 |

3 |

|

|

|

|

|

|

|

|

|

CWPPC-2 VG |

40 × 40 |

120 |

2/2800 |

|

|

24 |

22 |

20 |

12 |

8 |

|

|

|

|

|

|

|

CWPPC-3 VG |

40 × 40 |

150 |

3/2800 |

|

|

26 |

24 |

22 |

20 |

12 |

5 |

2 |

|

|

|

|

|

CWPPC-5 VG |

75 × 40 |

160 |

5/2800 |

|

|

35 |

33 |

31 |

30 |

27 |

25 |

15 |

0 |

|

|

|

|

CWPPC-7 VG |

75 × 50 |

160 |

7.5/2800 |

|

|

|

|

50 |

46 |

42 |

38 |

32 |

25 |

15 |

|

|

|

CWPPC-10 VG |

75 × 40 |

195 |

12.5/2800 |

|

|

|

|

|

|

|

|

45 |

42 |

33 |

25 |

15 |

Applications:

- Acid/Alkali Transfer.

- Recirculation Of Electrolyte.

- For Descaling of Tubes.

- Filter Press.

- Filtration Scribing of Corrosive Gases Like Cl2, Br2, So2.

Features:

- Design To Suit Extremely Corrosive Duties in Process & Chemical Industries.

- Less Expensive and Most Ideal Pumps Than Other Pumps Like as SS& Alloy Metals.

Range:

- Capacity: up to 60 m3/hr

- Size: 1" x 1" to 3" x 3 "

- Speed: up to 2800 rpm

- Pressure: up to 6.5 kg/cm2

- M.O.C: PP/PVDF/UHMWPE

Copyright by @ Care-Well Engineers. All Rights Reserved